Accuracy and precision are paramount in the construction field specifically when reinforcing concrete constructions.

It involves creating detailed drawings and specifications for placing, bending, and tying reinforcement steel (rebar) within concrete structures.

This ensures that the structure has the strength and stability to withstand various loads and stresses.

Indeed, the process of rebar detailing itself has undergone a sea change with the advent of BIM into the construction industry, adding much efficiency and capability to it.

What is Rebar Detailing?

Rebar detailing is the process of drawing up detailed designs and specifications for the size, configuration, and other details for the placing of rebars in concrete structures.

These details are important in determining whether the concrete structures can bear several loads and stresses to which they are exposed throughout their lifetime.

Rebar detailing entails the computation, with accuracy, of the size of bars, spacing, and bending shapes as per the requirements of structural engineering.

The rebar shop drawing process involves creating detailed drawings that specify the size, shape, and placement of each piece of reinforcing steel within a concrete structure.

These drawings are typically created based on the structural engineer’s design and are used by contractors and construction workers during the actual construction of the project.

Purpose and Importance of Rebar Detailing

Rebar detailing is necessary to provide proper planning and accuracy on the exact manner of laying and installation of the reinforcing bars.

- Structural Integrity: It assures that the concrete structure remains intact by avoiding cracks and consequently, any possible failure.

- Compliance: Detailed drawings must be necessary to ensure construction according to the codes and standards of engineering.

- Cost Efficiency: Accurate detailing reduces material wastage and minimizes the need for costly on-site modifications.

- Construction Accuracy: Represented drawings help in accurate and efficient installation, reducing errors and rework.

Benefits of Rebar Detailing

1. Enhanced Accuracy

Detailed plans allow for accurate placing of rebar at positions, improving the quality and strength of the overall concrete structure.

2. Smoother Workflow

Detailing, if done right, can aid construction procedures smoothly and integrate properly with various teams, from engineers to contractors.

3. Enhanced Safety

Rebar detailing leads to reduced errors and proper reinforcement of a structure, thereby providing a much safer output.

4. Saves Cost

Save a lot by reducing wastage and eliminating expensive changes at the site.

5. Integration of Technology

Advanced rebar detailing using advanced software and 3D modeling enhances visualization and communication across stakeholders. It improves accuracy and its integration with other components of buildings.

6. As-Built Documentation

Rebar detailing helps in the creation of accurate as-built documentation. The existence of such records aids in the regular maintenance and repairs of structures.

Common Challenges in Rebar Detailing and How to Overcome Them

In the traditional design of a reinforced concrete structure, many problems often crop up while doing 2D drawings. These can relate either to project efficiency or cost.

The following section looks at some of the problems associated with 2D rebar detailing and how 3D tools can offer effective solutions.

1. Collisions Between Steel Bars and Neighboring Structures

In 2D drawings, it’s easy to overlook collisions between steel bars and adjacent structural elements.

This can occur because 2D representations may not fully reveal spatial relationships, or because different drawings are used for various reinforcements without proper alignment.

BIM addresses this issue by providing a comprehensive view of the entire rebar model in 3 dimensions.

All reinforcement elements are visible in a unified 3D model, allowing for the early detection of collisions and interferences.

This visibility helps to identify and resolve conflicts before they manifest on-site, saving both time and material costs.

2. Interpreting Complex Structural Designs

Interpreting complex structural designs involves understanding fundamental engineering principles and examining detailed blueprints or 3D models to break down the structure into its core components.

Analyzing how loads are distributed and transferred through the structure is crucial, as is reviewing relevant building codes and standards to ensure safety.

Utilizing structural analysis software can provide valuable insights while consulting with experienced professionals can clarify intricate aspects.

Recognizing repeating patterns and considering the construction methods and design context further aids in comprehending the overall design.

3. Cross-planting Steel Bars at Joints

Accurate placement of steel bars, especially at joints, can be overlooked in 2D drawings, leading to confusion and extra reinforcement work, increasing costs.

3D design tools help identify overlaps and conflicts early by generating preliminary models based on design intent.

This allows for early detection of high-congestion areas and adjustments before construction begins.

4. Errors in Steel Bar Sizing Leading to High Costs

3D modeling tools can mitigate this problem by enabling a clearer view of each steel bar’s specifications.

In a 3D model, steel bars are marked distinctly and often color-coded based on their type and size.

This realistic rendering allows for easy identification and correction of errors early in the design phase, ensuring that all components are correctly specified before fabrication begins.

5. Design and Specification Change Management

It describes the process in which the proposed changes to the project are systematically documented and assessed for their potential effects on scope, budget, and schedule.

It is very important to update all the associated documentation and fully communicate its updates to the rest of the team and contractors.

In this manner, through careful implementation of changes with continuous, updated communications, you ensure your project will stay in line but be able to address changes easily.

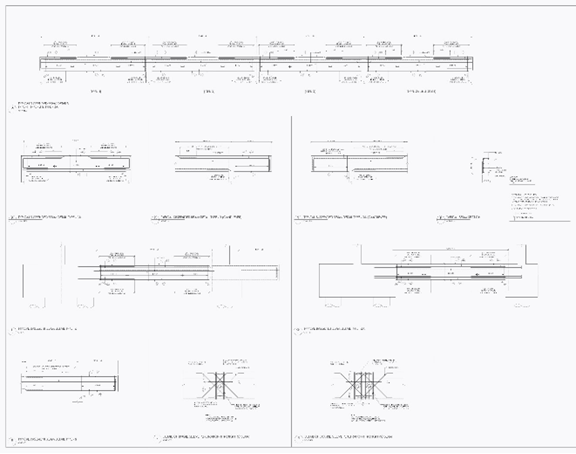

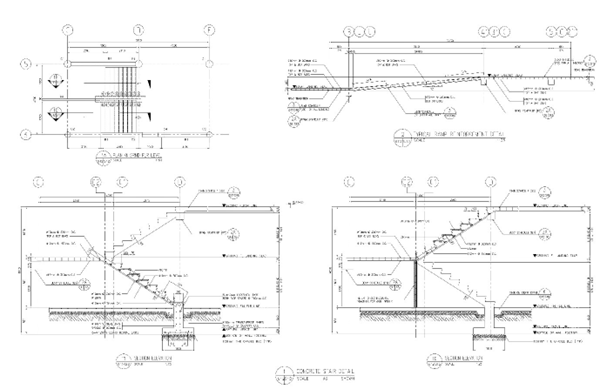

Examples of Rebar Shop Drawings

Rebar shop drawings are detailed diagrams that show how the rebar should be placed and tied in a concrete structure. These drawings typically include:

1. Rebar Specifications

Drawings that explain rebar assemblies in detail, denoting the types, sizes, spacing, bends, hooks, and other specifications indicating their proper positioning to ensure structural strength.

Explore: Why Do You Need Shop Drawings

2. Bar Bending Schedules

These are specific schedules which detail the bending shapes and dimensions for each rebar, with bar marks, sizes, and bending or hooking dimensions indicated.

3. Location and Spacing

Structural construction designs showing exactly where the rebars are sited within concrete elements such as beams and slabs to ensure their support and reinforcement.

4. Clear Cover

Clear cover specifications describe the space between concrete surfaces and the closest reinforcement bars.

5. Development And Lap Lengths

Guidelines on how to splice or lap bars to promote continuity and high tensile strength; these include the length of time it takes before they can effectively share force.

6. Anchorage Details

Information regarding anchorage into structural elements like foundations and footings stating any necessary conditions for seismic details, ties or hooks.

7. Material Specifications

The characteristics defining the type of reinforced steel and carted material specifications.

Examples can range from simple slabs to complex columns and beams, each illustrating the specific requirements for reinforcing different structural elements.

Rebar Detailing for Beams

Rebar Detailing for Stairs

Conclusion

Rebar detailing is one of those important aspects that help to ensure safe and durable concrete structures.

Now, with BIM, rebar detailing has become more accurate, efficient, and collaborative.

While there are still some challenges that remain, the use of advanced tools and practices will help to overcome them.

All in all, the result will be in having a better project outcome with enhanced structural performance.

The key for achieving excellence in rebar detailing and construction will remain embracing the development-based capabilities as the industry witnesses a paradigm shift.

Talk to our experts today for top-notch rebar detailing solutions!